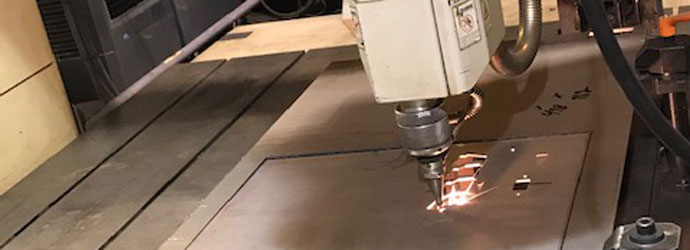

Aluminum Laser Cutting Services

Benefits of Our Laser Cutting Services

Laser cutters offer a number of benefits for industrial purposes. Whether you’re looking for a single custom piece or a wide range of laser-cut components, explore the benefits of working with Fusion Laser Services. We combine state-of-the-art laser cutting equipment with dependable engineering staff, so can turn to laser cutting for special projects with minimal preparation time or upfront investment on your part.

Reduced Production Time

A laser cutter operated by trained technicians offers reduced production time for your industrial needs. Compared to other cutting tools, a laser cutter doesn’t require new tooling for different types of cuts. It also doesn’t have a tool that needs to be maintained.

Physical tools have cutting blades that wear out, break and need to be serviced. Tool maintenance takes time and money, particularly in the form of downtime. Laser cutters create custom components without custom tooling manufacturing or swapping out existing tooling, so you can speed through a large- or small-batch order in less time.

Improved Cutting Precision

Some manufacturing components require cuts at precise angles and dimensions. Cutting blades have a set tolerance level, which may not be precise enough for your product. Instead of investing in a laser cutter for your facility, choose our cutting services at Fusion Laser Services. We can handle bulk orders or small-batch special projects to help you achieve industry-leading precision. Enjoy excellent tolerance levels and complex geometric shapes out of a variety of materials. Our machines work with mild steel, stainless steel or aluminum at tolerances of .005.

Discuss your designs with our engineering team to see how we can create a more precise product. Because we have a team of design engineers and laser cutting technicians, we offer less risk of miscommunication between the design and manufacturing stages. The result is a more efficient, precise process.

Less Waste Material Produced

Laser cutting is a highly efficient form of manufacturing. While the heat affected zone uses high-temperatures to cut through your aluminum or other alloy, this zone is quite small and won’t affect the tolerances of your component. Some light machining may be necessary for minute areas affected by the heat, but the rest of the material won’t be affected by the heat. Don’t worry about warping or collateral damage to your material, even if cutting a thin piece of aluminum.

A laser is an incredibly thin cutting component, which allows for higher sheet utilization compared to other cutting tools. Discuss your manufacturing process and material with our team to see how you can reduce your material waste or create additional components out of the same piece of material.

This form of manufacturing is also surprisingly energy efficient. Laser cutters can operate with just 10 kilowatts of energy, which is comparable or less than other manufacturing equipment. Even if you’re cutting thick sheets of aluminum, you can enjoy lower energy usage for an environmentally friendly and affordable service.

Improved Design Capabilities With Our In-House Team

Work with Fusion Laser Services to receive leading aluminum laser cutting services for your manufacturing needs. We not only have the equipment necessary for dependable manufacturing, but our in-house team of engineers can help you create components to fit your goals.

Our 2D and 3D cutting services make full use of our 3 axis and 5 axis lasers. Enjoy all the advantages of laser cutting without worrying about maintaining your own equipment. There are a few design considerations to make when working with extremely thick materials, so discuss your project with our team to be sure laser cutting is the most efficient option to hit your manufacturing goals and improve your bottom line.