All About 2D Laser Cutting 3D Laser Cutting Services

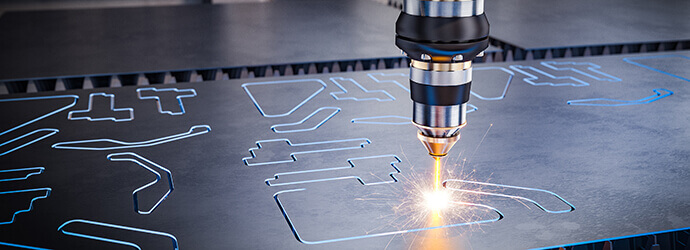

Laser cutting can be an immensely beneficial technology for slicing materials. It can be used in both a two-dimensional and three-dimensional setup to remove material from a variety of raw metals. The results of laser cutting tend to be very clean and highly precise.

Fusion Laser Services offers both 2D and 3D laser cutting services. Below, you can learn a little about our capabilities and why you may choose this form of fabrication.

Laser Cutting

As the name suggests, laser cutting uses a powerful laser to cut through the material. Typically, the laser is controlled by a computer through CNC. At Fusion Laser Services, we use three- and five-axis lasers controlled by trilogy laser software.

The system is fed a digital design. It then cuts the material based on that data. We accept PDF, IGS and STP files for laser cutting. This process can create a wide variety of 2D and 3D shapes.

To supplement our laser cutting, we offer some extra capabilities. These include assemblies, CNC machining, sandblasting, etching, welding, turning, stamping, metal fabrication, fixtures, product identification and parts tumbling.

Benefits of Laser Cutting

There are a lot of things to like about laser cutting. The following are a few of the most significant reasons why you may choose this fabrication technique:

- Fast: Lasers can cut through metals including aluminum, steel and stainless steel with ease. This makes the process of making cuts much faster. Time saved cutting materials can translate to improved productivity and bottom-line results.

- Economical at Small Orders: Both 3D and 2D laser cutting can be economical even at relatively low volumes. There is no or minimal retooling necessary in most cases thanks to the laser’s built-in capabilities.

- Ideal for Rapid Prototyping: The above two benefits make laser cutting perfect for rapid prototyping. If you want to get to market quicker, this may be the right option for you. We will even help you to adjust your design to achieve your desired requirements.

- Highly Precise: The cuts made by a laser are very precise. There are no tooling marks and minimal discoloration. Therefore, what you design is exactly what you get. Better yet, this means that you will need less material to produce the same amount of product.

- Clean: Cuts made by a laser are very clean. The quality is consistent, and your tolerances can be very tight.

2D Laser Cutting Services

Our 2D services are provided with a three-axis laser. This is also known as flatbed cutting because the laser treats the material as a single plane. The laser cuts the material straight through and the pieces drop out as they are cut. 2D laser cutting can start at any point in the material and make any two-dimensional shape.

3D Laser Cutting Services

Our 3D services work similarly but have a five-axis laser to allow for the third dimension. The laser can produce a variety of cuts with high accuracy and repeatability. Metal parts can be made to fit different geometry with narrow tolerances.

Laser Cutting Applications

Laser cutting can be used for almost any form of metal cutting and fabrication. When combined with our additional services, our 2D and 3D laser cutting are only limited by creativity. By applying laser cutting, you could take your product from idea to reality sooner.

As mentioned above, laser cutting is well-suited for rapid prototyping and low-volume manufacturing. However, it can also be used to rapidly and accurately produce both high-volume orders and time-tested designs.

This technique is used in aerospace, automotive, electronic, medical and semiconductor applications. At Fusion Laser Services, we have applied laser cutting to make both small, highly precise parts and full products.